hydro power plants

Monitor the health of bearings and gearboxes of critical plants successfully. Mechmine offers a secure and powerful solution.

Hydro power plants: our offering for plants below 10MW

| Stable operations: thanks to 24/7 continuous condition monitoring and health prediction | |

| Maximum component lifetime: exploit the remaining useful life of components thanks to artificial intelligence (AI) and reduce waste | |

| Simple and safe operation: thanks to the intuitive and user-friendly interface | |

| Integration into your system: present analysis result in your control system, e.g. show trends in Remec's Sambesi | |

| Highest level of data protection: autonomous and passive AI-system, independent of your IT or control software |

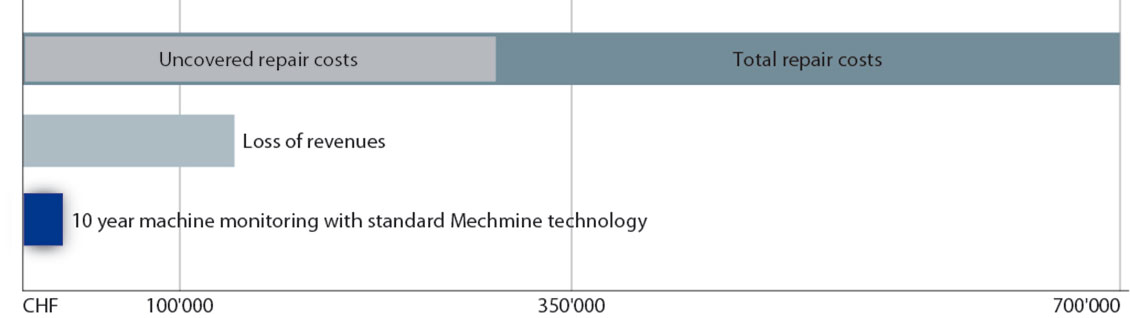

Costs - benefits: amortization of the Mechmine solution in 7 to 22 months

A 1500 kVA hydro power station in Switzerland had a defective shaft (rupture) due to a bearing issue. The total repair costs amounted to CHF 700'000 whilst the insurance covered CH 400'000. The production loss lastet 60 days, or around CHF 135'00 subject to market prices. Thus the total costs amounted to CHF 435'000.

Mechmine technology

Mechmine increases your system availability by changing from condition monitoring to predictive maintenance. Determine the time of maintenance and repair yourself. Successfully monitoring bearings, gears and turbines in your assets. Mechmine offers a secure retrofit turnkey solution - access from anywhere, anytime and comprehensible to everybody.

Continuous monitoring & forecasting, 24/7

- From condition monitoring to predictive maintenance

- Increased plant availability

- Turnkey solution, everything from one source

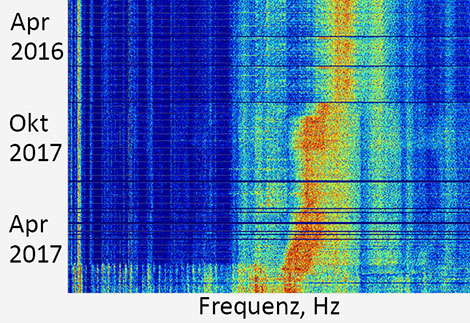

Highest data quality & data analysis performance

- Optimized hardware for turbines, gearboxes, high-RPM shafts

- Making cavitation visible

- Special vibration sensors for slow-moving machines

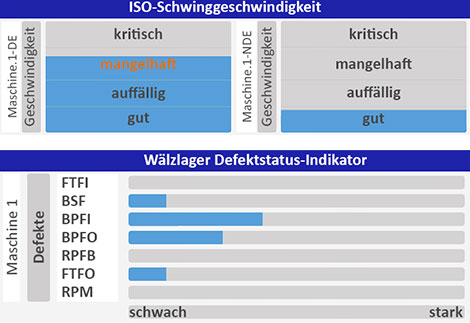

- Early detection and warning of upcoming defects and affected component

Intuitive user interface

- Appropriate and user-tailored visualization through several levels

- Traffic light – trends – details

- Data and trends can be displayed in any control system

References and examples

-

SAK Flusskraftwerk mit Getriebe

-

Elektrizitätswerk EV Vilters Wangs

-

Electricity utility EW Vilters-Wangs

-

Smaller hydraulic power station from SAK with gearbox

Exemplary illustrations

Mobile access

Mobile access Dashboards

Dashboards Early detection of anomalies

Early detection of anomalies