Imbalance-Alignment-Looseness Tool

Machine errors like imbalance, misalignment or looseness account for the majority of issues in rotating machines. Therefore, their fully automated identification is of high relevance and...

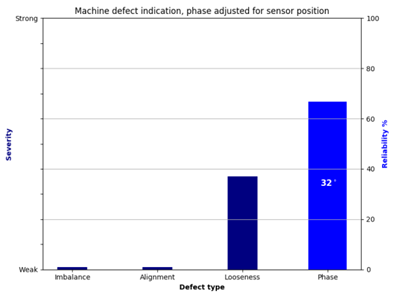

...our customers will have the best tools at their disposal. Mechmine provides an IAL-Tool (imbalance-alignment-looseness) to assist the experienced professional in assessing machine faults. For the non-vibration expert, a dashboard is provided that shows the severity of each of the three machine faults, see 1st image below. The calculated phase shift between the two opposing vibration sensors is also displayed, supported by an indicator describing the reliability of the phase angle, see right bar in 1st image below. To increase the quality of the evaluation, four different algorithms were implemented, because no single method works reliably or is robust for all machines or machine conditions. The four results are then reduced to one result in a fusion process, taking into account the reliability determined for each algorithm.

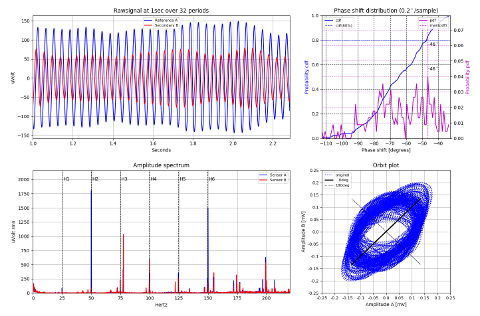

The IAL-Tool displays, see 2nd image above, also the raw data, i.e. the rotational frequency, the corresponsing frequency spectrum, an orbit plot and the statistical distribution of the phase shift between the measurement signals. This allows the user to understand the results in the dashboard and to perform another measurement if he deems it necessary, e.g. in presence of very strong amplitude modulation.